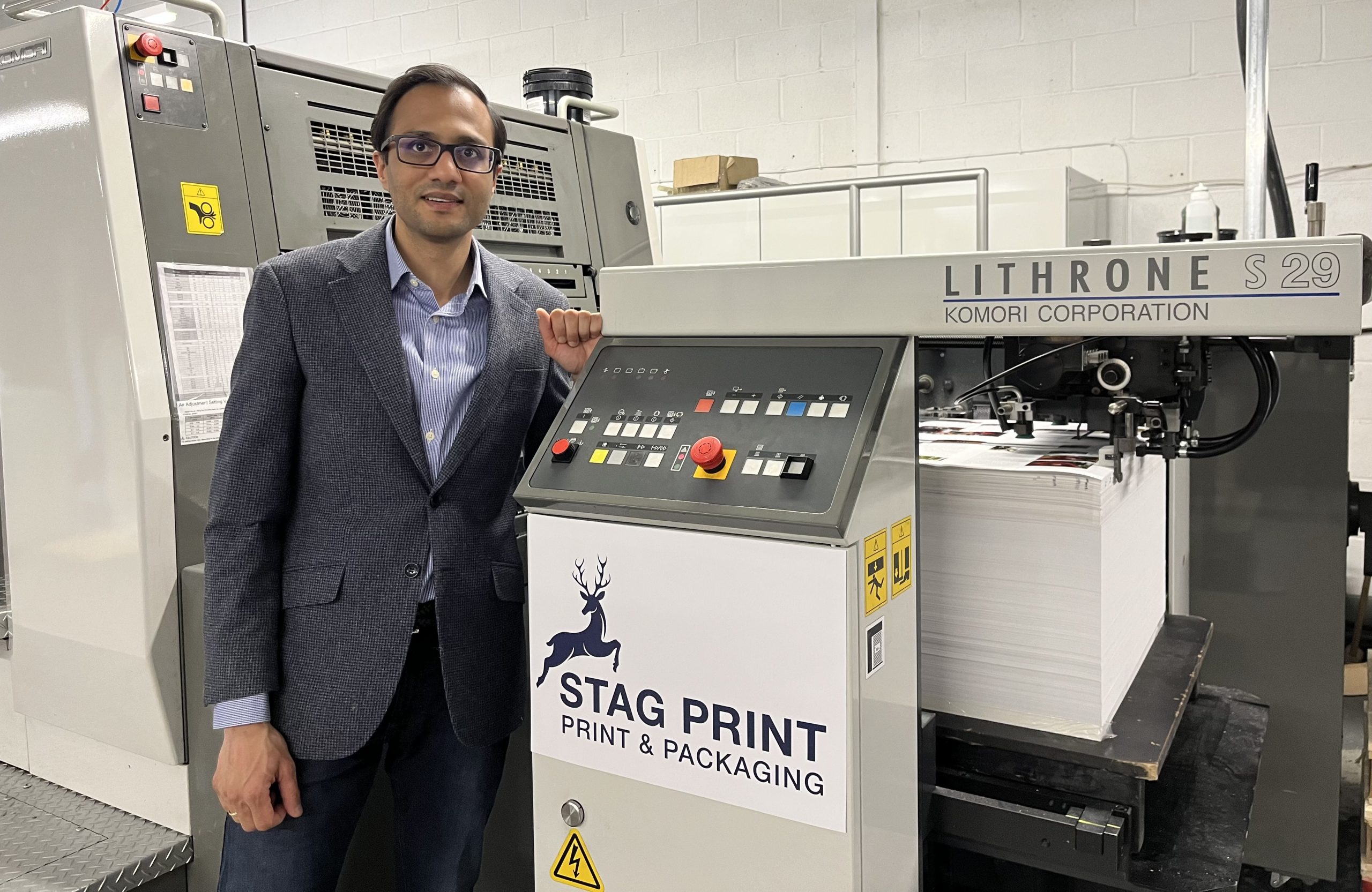

Stag Print is pleased to announce its investment in a state-of-the-art Komori LS29 print machine enabling it to double its production capacity.

The press is 11 metres by 5 metres in size and weighs 20 tonnes, making it bigger and better than any other machine the company has used before. With the added bonus of being extremely efficient and better for the environment.

The family-owned Surrey business with a 44-year heritage has also recruited a second highly experienced operator to run the machine.

Sushil Patel, managing director, Stag Print, said:

“It’s been a very busy start to 2023. The installation of the Komori LS29 in January, along with the arrival of our new team member, means we are full steam ahead and foresee an exciting year of growth for Stag Print.”

The machine is a huge leap in our production capability – from quality and efficiency to environmental impact. We can now cater for a much wider customer base and further increase our reach to manufacture point of sale boxes for the cosmetics, pharmaceuticals, and bottled spirits sectors.”

Technically speaking, the Komori LS29 offers:

Exceptional quality

- Air venturi system so paper glides on an airbed allowing print on up to 0.8mm board.

- Guaranteed colour reproduction using an ISO calibrated ink densitometer.

- Ink temperature control to ensure colour consistency throughout production.

Extra efficiency

- Faster production time increasing output speed by 40%.

- Faster setup time reduced from 45 minutes to 15 minutes.

Environmentally friendly

- Greenest litho press around with a state-of-the-art LED UV drier.

- Alcohol-free, unlike conventional presses, so less polluting.

- Lower energy consumption due to faster production and faster setup times.

See it in action via our video.